Anti-static Devices in Ball Valve

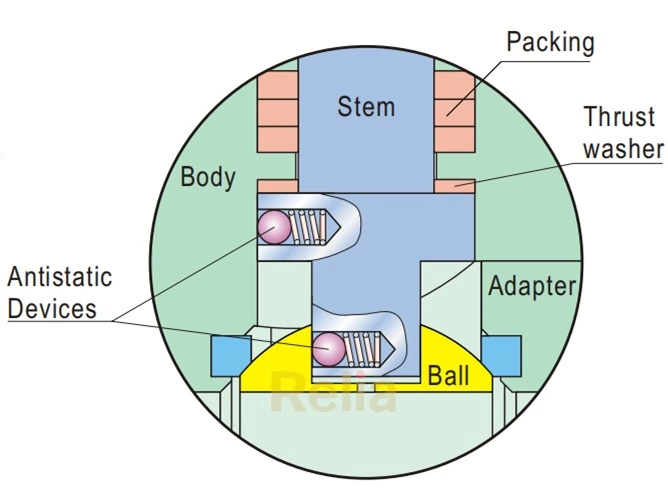

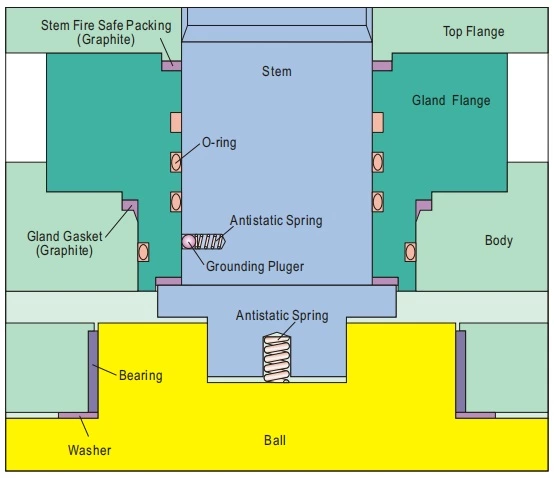

An anti-static device used in a ball valve is to reduce the static charge generated on the ball due to friction. It is used to protect the valve against sparks that may ignite the fuel flowing through the valve.

Anti-static Device In Ball Valve

The ball valve with an anti-static design is especially important for fields such as oil and gas, chemical, power plants, and other industries. For these industries, fire-free production is an important guarantee of safe production.

During the operation of the valve, the constant friction between the ball and the soft seat will generate static electricity. The anti-static device is the standard design for ball valves manufactured by Relia.

Anti-static Design In Trunnion Ball Valve

All welded valves manufactured by Relia only have the potential to accumulate charge in the sphere, so the electrostatic design is as follows: the stem is equipped with a spring and a ground plug, so that the ball forms a conductor between the stem and the valve body, and the static charge can be transferred from the sphere to the grounding device through the stem and valve body, thus avoiding the accumulation of static charge. This accumulation of static can be extremely dangerous in some areas.

Anti-static Testing

As API 6D specifications, the electrical resistance between the obturator and the valve body and between the stem/shaft and the valve body shall be measured using a D.C. power source not exceeding 12 V. The resistance shall be measured on dry valves before pressure testing and shall not exceed 10 Ω.

Ball Valve Anti-static Device Inspection