Double Block And Bleed Ball Valve

Double Block and Bleed Valves are a combination of one or more block/isolation valves, usually ball valves, and one or more bleed or vent valves, usually ball or needle valves.

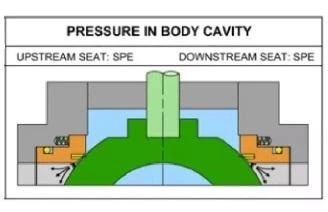

Double Block and Bleed Valves work on the principle of isolation fluids and pressures from both upstream and downstream.

Single Trunnion Ball Valve Double Block and Bleed (single piston seat)

API 6D defines a double block and bleed valve as a "single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve with a means of venting or bleeding the cavity between the seating surfaces."

Double Block

The trunnion ball valve combines double block and bleed functionality in a single valve.With a DBB trunnion ball valve, there are usually two unidirectional self-relieving seats. When the ball valve is closed, medium pressure from both upstream and downstream creates the resultant thrust on the seat to push the seat ring against the ball to assure a tight seal. That means one seat is to block the upstream flow, and the other seat is to block the downstream flow separately.

Bleed

Ball valves can trap fluid in the body cavity when they are closed. If the liquid heats up, it will increase the pressure in this cavity as a result of fluid expansion. The fluid pressure in the body cavity creates a resultant thrust that pushes the seat rings away from the ball. The single piston design permits the automatic release of any overpressure in the body cavity to the internal pipeline.

Single Trunnion Ball Valve With Double Block and Bleed

The self-relieving seat is triggered by differential pressure in the body cavity and pipeline. The body cavitv pressure should not exceed 1.33 times the valve pressure rating at the specified maximum operating temperature; however, self-relieving action usually happens long before, with just a few bars of differential pressure. For standard API 6D ball valves, both seats are self-relieving. However, on request, valves can be ordered with just upstream or just downstream seat for self-relieving.

Two Block Valves (twin ball valves) and One Bleed or Vent Valve (usually ball or needle valves)

Isolation can be achieved from both the upstream and downstream fluid flows and pressures by two block valves (twin ball valves) with a third bleed valve (usually a needle or ball valve) in the center cavity. Once one or more of the main process isolation valves have been isolated, the cavity created between these isolation valves can be drained using the bleed valve. Bleed valves will either be vented directly to the atmosphere locally or via a hose connection or piping to an appropriate closed disposal system.

Twin Ball Double Block and Bleed Ball Valve

The purpose of the block and bleed valve system is to isolate or block the flow of fluid in the system so the fluid from upstream does not reach other components of the system that are downstream. It enables the pipeline to bleed off, vent, or drain the remaining fluid from the system on the downstream side in order to execute some kind of work (maintenance, repair, or replacement), such as sampling, flow diversion, chemical injections, integrity checks for leakage, etc.