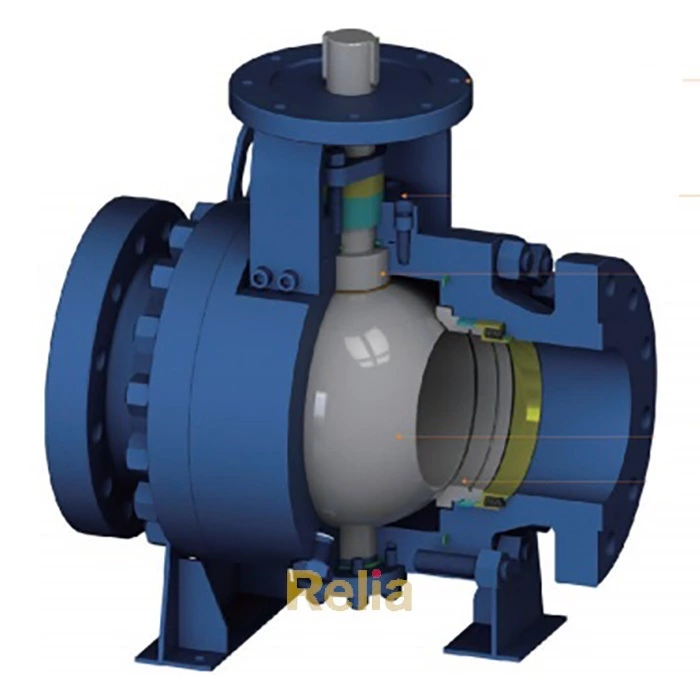

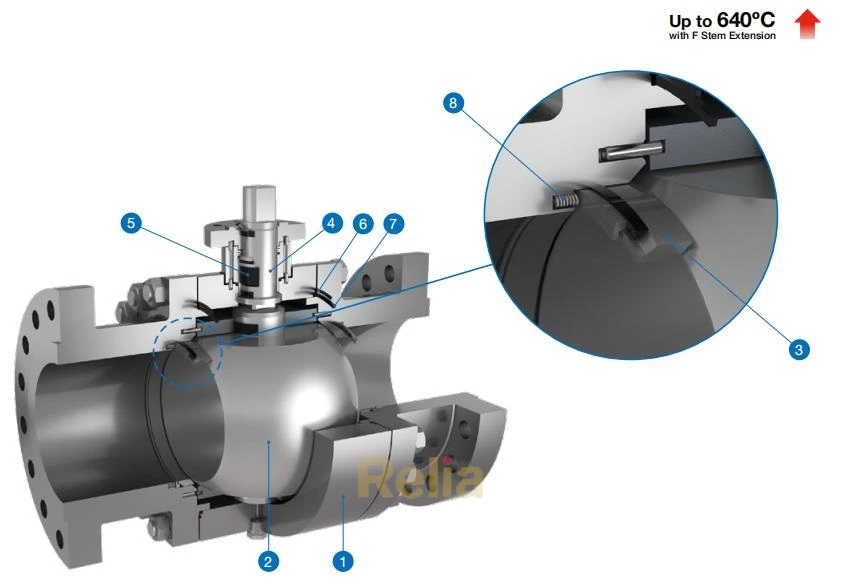

Metal Seated Trunnion Ball Valve

Metal-seated trunnion ball valves are resistant to abrasion, erosion, corrosion, solids, and high temperatures up to 640℃. Special metal-seated ball valves are available in high pressure, big size, top entry, etc.

The metal seated ball valve leakage rate meets the highest standard of EN-12266, ISO 5208, ANSI FCI 70.

There is wide selection of coating materials, such as Chrome Carbide (CrC), Hard Chromium (HCr), Tungsten Carbide (WC-Co), Cobalt Based Alloy, and Stellite 6 etc.

Relia’s scraper seat is ideal for most difficult applications where build-up of damaging fluid deposit may occur on the ball face.

- Size

- 2"~40"

- Temperature Range

- -29~640℃

- Pressure Rating

- Class 150~2500

Features and Benifit

Corrosion / Erosion Resistance

- Extend the life of metals with a wide selection of surface coatings, available for valve internal / externals. These coatings include Teflon, chrome, electroless nickel, zinc phosphate,tungsten carbide galvanizing & many more options.

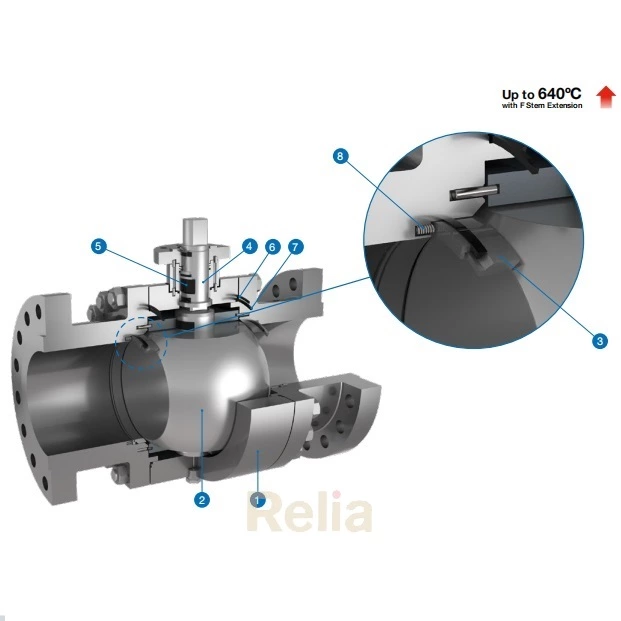

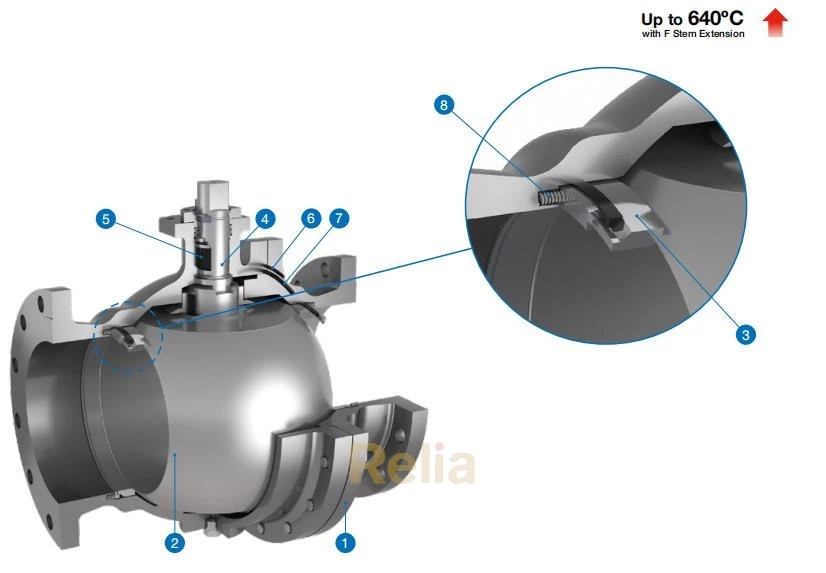

Ball & Seats

- Mate-lapped for 100% sealing contact

- Ensures absolute shutoff per ANSI classification

- Corrosion resistant

- Seats are protected from flow in open / closed position

- Seats are available as field replaceable sets

Seat Spring

- Assisted by line pressure, provides a constant mechanical force on ball against seat to maintain a tight seal

Body Gasket

- Encapsulated spiral wound body seals guarantee zero leaks to the surrounding area.

- Lowers contact stresses

Drawings

- Cast Steel Metal Seated Trunnioin Mounted Ball Valve

- Forged Steel Metal Seated Trunnioin Mounted Ball Valve

Typical Material

| Item | Part Name | Material | |

| Cast Steel | Forged Steel | ||

| 1 | Body | A216 WCB | ASTM A105 |

| 2 | Ball | F316+TCC | |

| 3 | Seat | F316+TCC | |

| 4 | Stem | XM-19 | |

| 5 | Stem packing | Graphite | |

| 6 | Body Seal 1 | Graphite | |

| 7 | Body Seal 2 | Graphite | |

| 8 | Seat spring | Inconel X-750 | |

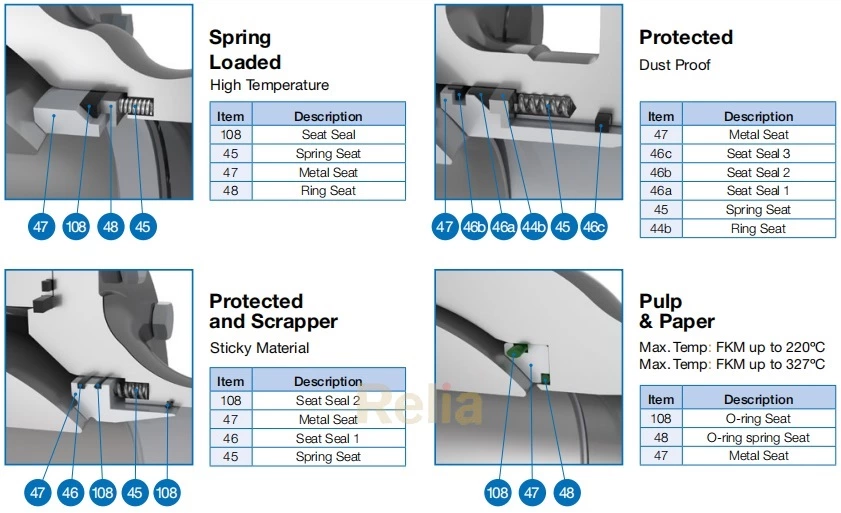

Seat Models

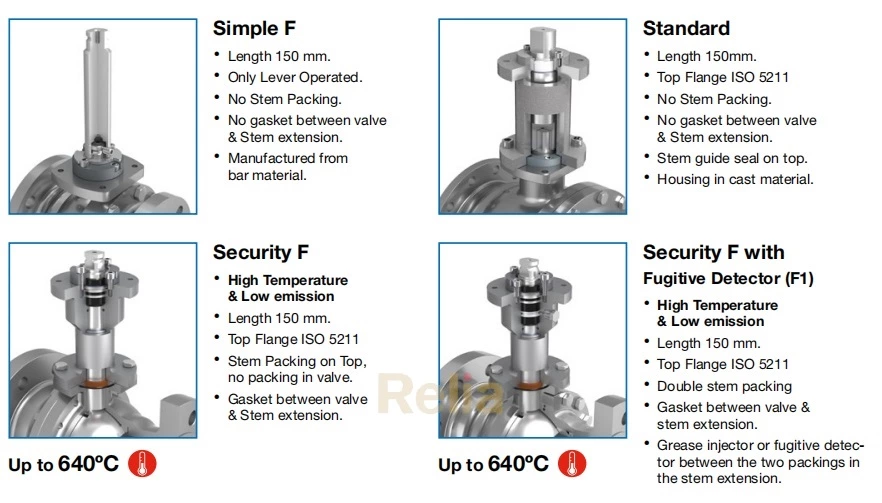

Stem Extentions

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)